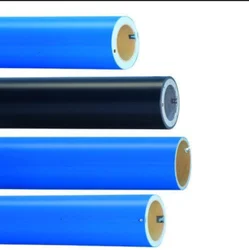

Re-Covered Rubber Roller

Re-Covered Rubber Rollers are refurbished rollers with a new layer of high-quality rubber applied to their surface, offering enhanced durability, improved performance, and cost-effective solutions for industries needing consistent material handling and precision.

Re-Covered Rubber Rollers are an efficient and cost-effective solution for industrial operations that require reliable and high-performance rollers without the need for full replacement. These rollers are refurbished by applying a new layer of high-quality rubber to the roller core, restoring their functionality and extending their service life. The process of re-covering involves removing the worn-out rubber and replacing it with fresh, durable rubber that meets the specific requirements of the application.

Re-Covered Rubber Rollers are commonly used in industries like printing, packaging, material handling, and manufacturing, where smooth, reliable material movement and consistent pressure are essential. The new rubber layer ensures optimal grip, minimal slippage, and even application of inks, adhesives, or coatings. These rollers also offer enhanced resistance to wear, chemicals, and abrasion, ensuring long-lasting performance in high-speed and heavy-duty environments.

The re-covering process provides a cost-effective alternative to purchasing entirely new rollers, making it an attractive option for businesses looking to maintain high-quality production standards while managing costs. Re-Covered Rubber Rollers are ideal for applications that demand precise tension control, excellent surface quality, and high durability, ensuring smooth and uninterrupted operation across various industrial processes.

By opting for Re-Covered Rubber Rollers, industries can reduce downtime, minimize waste, and maintain efficient operations, all while extending the lifespan of their roller components.

Reviews

There are no reviews yet.