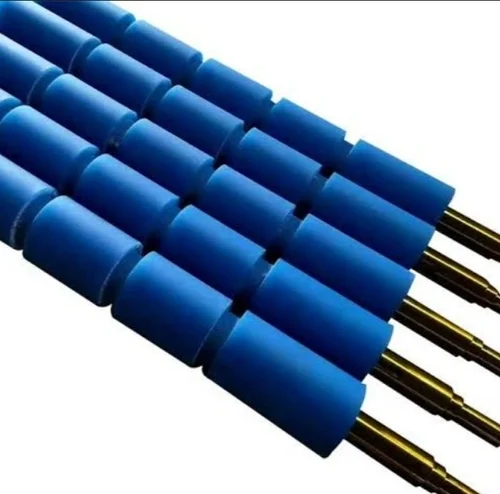

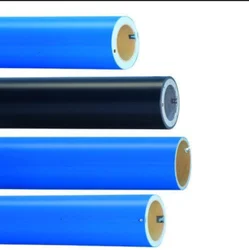

Corona Rubber Roller

Corona Rubber Rollers are specially designed rollers used in the corona treatment process to improve the surface adhesion of materials, ensuring superior ink, coating, and adhesive bonding in printing and packaging industries.

Corona Rubber Rollers are critical components in the corona treatment process, a method used to increase the surface energy of materials like plastics, films, and foils, enhancing their adhesion properties. These rollers work by applying a high-voltage corona discharge to the surface of the material, improving its ability to bond with inks, coatings, adhesives, and other substances. They are typically used in industries such as packaging, printing, and laminating, where consistent and reliable material treatment is crucial for high-quality results.

Made from high-quality rubber compounds, Corona Rubber Rollers provide excellent durability and resistance to wear, heat, and chemicals, ensuring they can withstand the demanding conditions of the corona treatment process. The rubber material helps distribute the corona discharge evenly across the material’s surface, ensuring uniform treatment and preventing inconsistencies that could affect the quality of the final product.

Corona Rubber Rollers are engineered to maintain excellent grip and consistent performance over time, ensuring smooth operation even in high-speed production lines. They play a vital role in improving the quality of printed materials, packaging films, and other substrates by ensuring that inks and coatings adhere properly, which ultimately enhances the performance and appearance of the finished product.

Overall, Corona Rubber Rollers are essential in industries where surface treatment is necessary to improve adhesion and enhance material performance, offering long-lasting and reliable results in a variety of manufacturing and printing processes.

Reviews

There are no reviews yet.